Thermal contact conductivity - first tryout

I like this feature - it offers a way to avoid modelling fiddly little thin layers. I think that TCC = CTC/thickness (where TCC = thermal contact conductivity, CTC= coefficient of thermal conduction), but I have a vague recollection of suggesting a similar idea that you could avoid modelling super-thin layers by modelling them thicker and changing the CTC proportionately. I think Victor may have tried a demo that showed this not to be the case. I need to check.

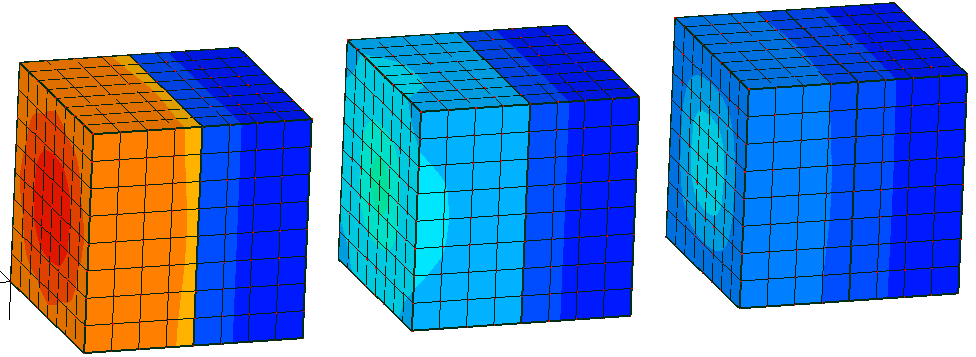

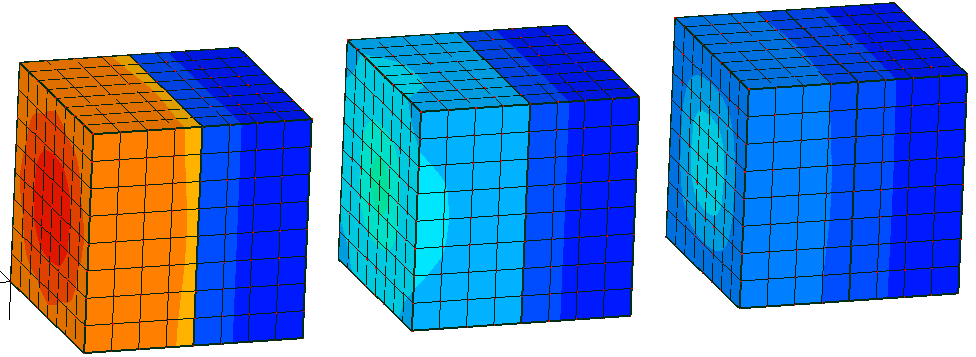

My first attempts to use this feature were in a solid lump , just selecting identical slave/master faces from opposite directions. This did not work. So I made two separate components with faces in the same plane and it worked fine. I haven't tried physically separating the faces to see if the feature still works. The image shows three similar trials with an identical wattage going in on the central area of the LHS face, and an identical convection at the RHS face. The TCC decreases by a factor of 10 from left to right. It's obvious where the contact is

Just to add, I LOVE working with the 3D Connexion mouse in Mecway. This software just gets better and better to use -great work Victor, and thank you.

.

My first attempts to use this feature were in a solid lump , just selecting identical slave/master faces from opposite directions. This did not work. So I made two separate components with faces in the same plane and it worked fine. I haven't tried physically separating the faces to see if the feature still works. The image shows three similar trials with an identical wattage going in on the central area of the LHS face, and an identical convection at the RHS face. The TCC decreases by a factor of 10 from left to right. It's obvious where the contact is

Just to add, I LOVE working with the 3D Connexion mouse in Mecway. This software just gets better and better to use -great work Victor, and thank you.

.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Comments

To be honest, I'm never quite clear on the definitions of all those TCCs and CTCs and all that. I named the parameter using what I hoped was the more obvious term "thermal conductance" (=1/thermal resistance). But it turns out that's fairly uncommon and even ambiguous. So it's sadly a giant mess. Sounds the same as what you said though - thermal conductivity / thickness.

It uses contact in CCX, so the same behavior for finding which faces to connect applies, which allows some gap between the two meshes.

If you lump in crystal defects, contaminants etc. that sometimes accumulate at interfaces, you can describe a bigger thermal barrier that includes the non-intrinsic stuff. I reckon you could follow the modelling and maths (I can't), but whether you would want to go to the trouble is another matter. Shout if you want copies of the papers. Julian Anaya is one of the people who has done much of the recent work that I have seen. He's cleverer than me by some way, but he's also very helpful and (mercifully) tolerant of dumb questions, so look him up if you're interested, or I can ask for contact details.