Contact: Test Model

Hi Everyone,

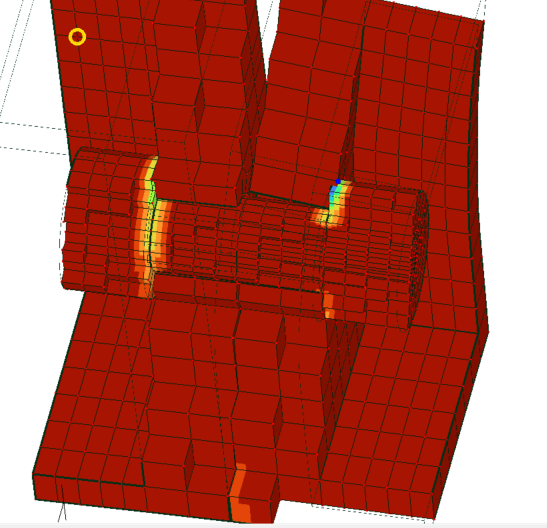

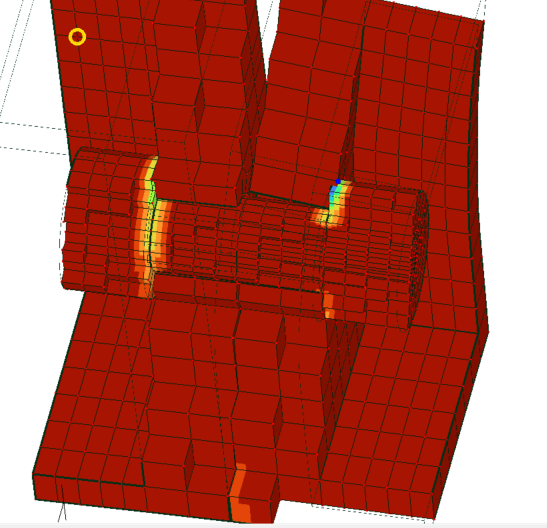

I’m working on developing a typical contact model (very small model) for a bolted-type connection. In some unique situations, this approach might be necessary to determine the ultimate capacity of the connection. This is a test model designed to simplify the elements, as performing a single bolted connection analysis is uncommon.

Could you please verify whether the level of contact displacements is acceptable? It seems there’s a 1mm indentation of one surface into the other. Additionally, the model fails to converge if I set the normal stiffness per unit area to more than 900 GPa/m. Typically, the bolt would fail under this level of stress; however, I’ve set the bolt material to behave elastically in this case.

Your suggestions and feedback are greatly appreciated.

I’m working on developing a typical contact model (very small model) for a bolted-type connection. In some unique situations, this approach might be necessary to determine the ultimate capacity of the connection. This is a test model designed to simplify the elements, as performing a single bolted connection analysis is uncommon.

Could you please verify whether the level of contact displacements is acceptable? It seems there’s a 1mm indentation of one surface into the other. Additionally, the model fails to converge if I set the normal stiffness per unit area to more than 900 GPa/m. Typically, the bolt would fail under this level of stress; however, I’ve set the bolt material to behave elastically in this case.

Your suggestions and feedback are greatly appreciated.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Comments

But that kind of lateral movement of the bolt only happen at very high loads and only if the bolted union was not well designed.