Layered shells with mixed material models.

HI,

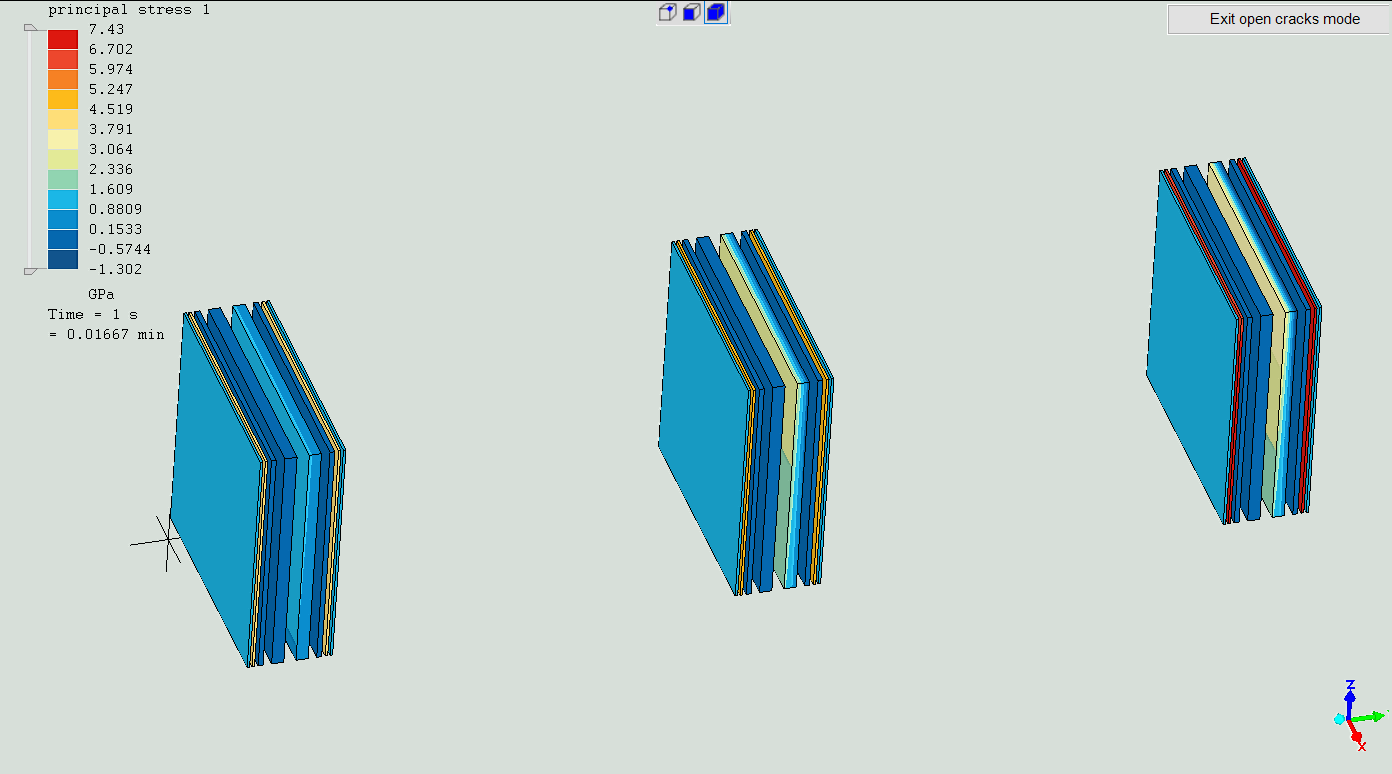

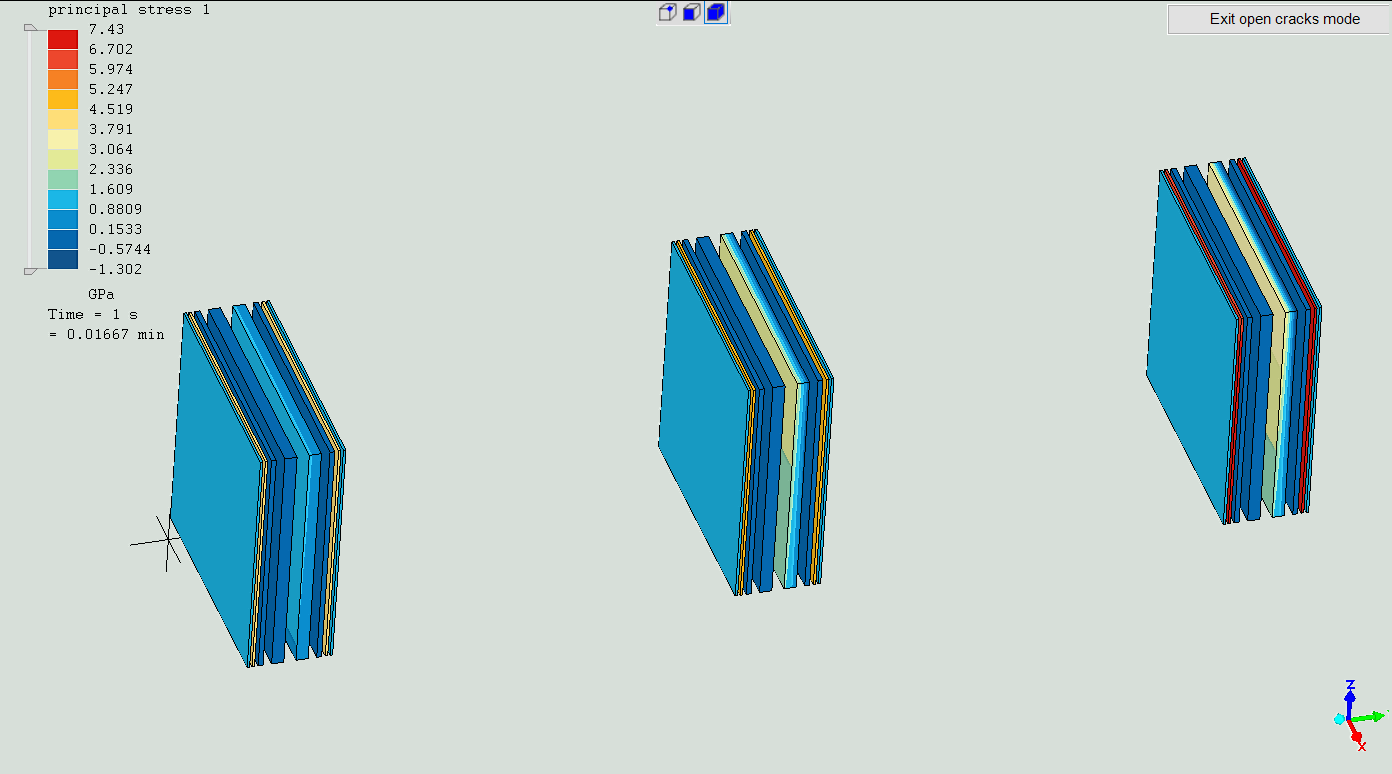

Some days ago, I had access to an interesting ccx inp file. I found that layered shells can contain orthotropic elements with isotropic elastic materials all in the same Shell section definition.

Not been that enough I have recently discover that one can even have plastic or hyper elastic layers in between, opening the door to a new set of capabilities.

Gaskets which typically mix rubbers, vegetable fibers, carbon fibers or metallic insertions could be modeled.

I have modeled a composite build with plastic, elastic, orthotropic and hyperplastic materials all them together. Mecway has not complain to process the results (even shows the PEEQ value just for the plastic layer). I would like to ask if someone knew about this possibility and has some experience or warnings about it.

I suppose it can be hard to validate or even verify one of this tutti-frutti so any possible comment respect them is appreciated.

If you didn’t know about it I encourage you to try.

Main Custom card looks like this with its corresponding previous material definition.

*SHELL SECTION,COMPOSITE,ELSET=Uniaxial_Tension,offset=0.0

0.00001,,Gelcoat

0.00001,,Glass_biax

0.00002,,medium_density_foam

0.00005,,S235_DNV

0.00005,,OGDEN_Intima

0.00002,,medium_density_foam

0.00001,,Glass_biax

0.00001,,Gelcoat

Regards

Some days ago, I had access to an interesting ccx inp file. I found that layered shells can contain orthotropic elements with isotropic elastic materials all in the same Shell section definition.

Not been that enough I have recently discover that one can even have plastic or hyper elastic layers in between, opening the door to a new set of capabilities.

Gaskets which typically mix rubbers, vegetable fibers, carbon fibers or metallic insertions could be modeled.

I have modeled a composite build with plastic, elastic, orthotropic and hyperplastic materials all them together. Mecway has not complain to process the results (even shows the PEEQ value just for the plastic layer). I would like to ask if someone knew about this possibility and has some experience or warnings about it.

I suppose it can be hard to validate or even verify one of this tutti-frutti so any possible comment respect them is appreciated.

If you didn’t know about it I encourage you to try.

Main Custom card looks like this with its corresponding previous material definition.

*SHELL SECTION,COMPOSITE,ELSET=Uniaxial_Tension,offset=0.0

0.00001,,Gelcoat

0.00001,,Glass_biax

0.00002,,medium_density_foam

0.00005,,S235_DNV

0.00005,,OGDEN_Intima

0.00002,,medium_density_foam

0.00001,,Glass_biax

0.00001,,Gelcoat

Regards

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!