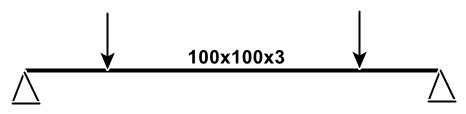

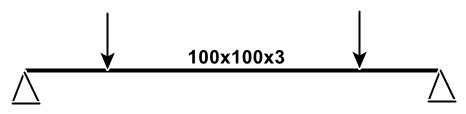

Pipe buckling

I had a problem with a 100x100x3 square pipe collapse. See attached picture and static scheme. The problem is referred to understand the failure mode: resistance or local buckling. The pipe is undersized but, designing the new one (maybe 100x100x6 or 8 thickness - Outer dimenions shall be 100x100) I want to be sure that there will not be problem referred to local buckling.

What kind of analysis will be more near to the real conditions? I think non-linear buckling.

Other problem is related to the loads because they are transmitted by a contact

What kind of analysis will be more near to the real conditions? I think non-linear buckling.

Other problem is related to the loads because they are transmitted by a contact

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Comments

If you send me the loads I can give some guidance on the equations.

How much are the vertical shear forces?

Regarding the picture, it look like a bending excessive failure.

Maybe local buckling depending on the shear force and the contact area.

I am thinking about the material quality how is it? European standard S235/355? Stainless steal or another one? It happend some times that there is a bad process which results to a wide decrease of the mechanical strengh when we buy to a foreign uknown steel provider company...

So could you give us more inputs? I am gonna check in accordance with EC3 (steel maybe?) by simple hand made analysis in a first approach

BR