Cheating Convergence

While debugging problematic models, I often relaxed the convergence criteria with a custom card like *CONTROLS,PARAMETERS=FIELD

**Defaults = 0.005, 0.01, 0.01, , 0.02, 10-5, 10-3, 10-8

1,1,.1,,0.02,1.E-5,1.E-3,1.E-8

While this often enables me to get to some sort of solution or to certainly see if I have made some fundamental set up error -I'm never really sure how badly it affects the accuracy of the solution. Any pointers here would be great.

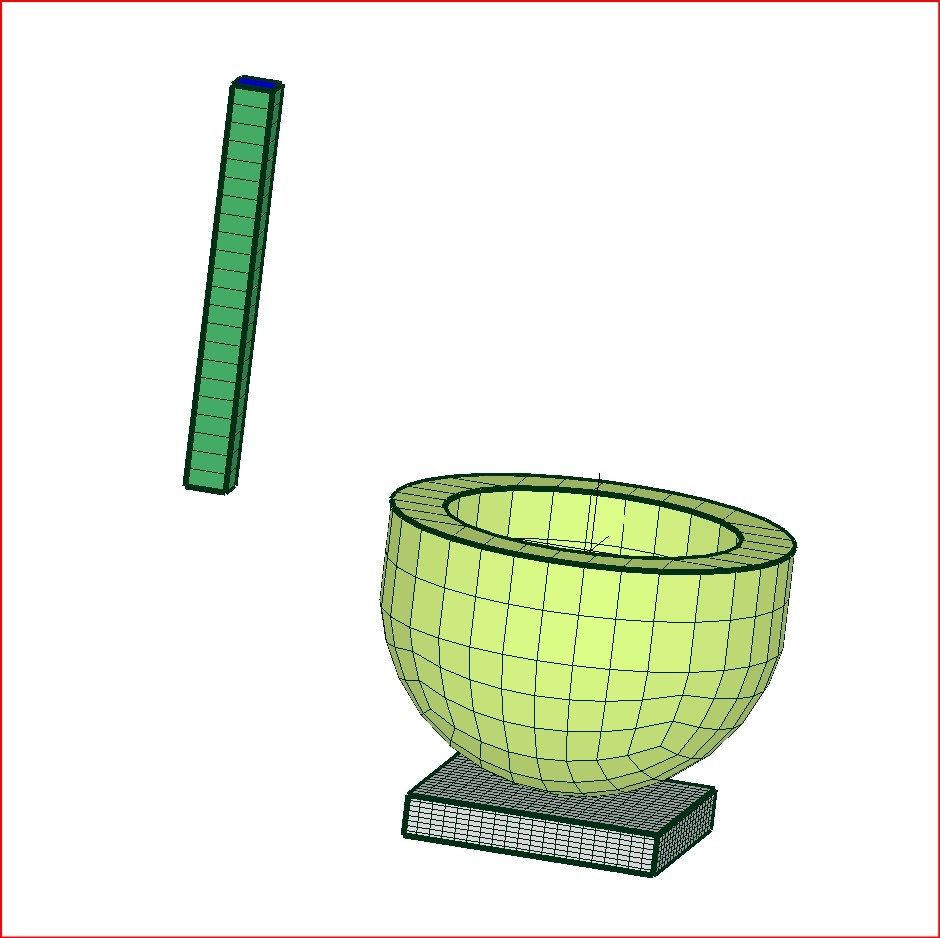

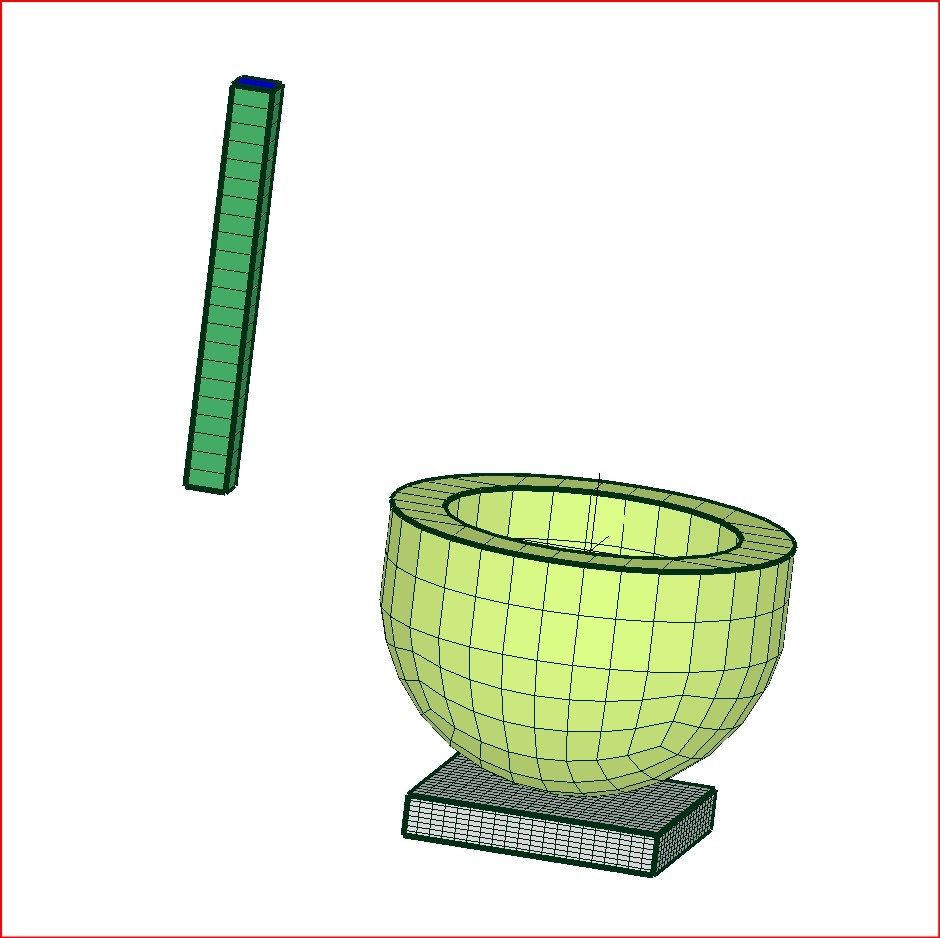

I have also been trying another cheat by including a separate dummy body that generates high stresses and high deformations along side the main model. I used a tall cantilever. In the attached model i have set up a very basic dome/plate contact analysis and purposely selected parameters that stop it converging (in this case I put a high friction coefficient in the contact that stopped the model getting past 0.6s).

With the dummy cantilever included, the analysis runs all the way to the end.

Is this the same as fiddling around with the field control parameters? Again how much would it make you question the main model solution? Also it got me wondering if there is potential for a situation in a large mutli part model with varying materials present where the legitimate deflections/stress in on area allowed the convergence tests to continue despite another area of the model behaving in a manor that would prohibit convergence if it occurred in isolation?

**Defaults = 0.005, 0.01, 0.01, , 0.02, 10-5, 10-3, 10-8

1,1,.1,,0.02,1.E-5,1.E-3,1.E-8

While this often enables me to get to some sort of solution or to certainly see if I have made some fundamental set up error -I'm never really sure how badly it affects the accuracy of the solution. Any pointers here would be great.

I have also been trying another cheat by including a separate dummy body that generates high stresses and high deformations along side the main model. I used a tall cantilever. In the attached model i have set up a very basic dome/plate contact analysis and purposely selected parameters that stop it converging (in this case I put a high friction coefficient in the contact that stopped the model getting past 0.6s).

With the dummy cantilever included, the analysis runs all the way to the end.

Is this the same as fiddling around with the field control parameters? Again how much would it make you question the main model solution? Also it got me wondering if there is potential for a situation in a large mutli part model with varying materials present where the legitimate deflections/stress in on area allowed the convergence tests to continue despite another area of the model behaving in a manor that would prohibit convergence if it occurred in isolation?

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Comments

The way I solve mysterious convergence problems is usually fixing every part and/or softening contacts until it works, then releasing things until it breaks. But there's also a way to get the results from the last iteration which might reveal what's moving where.