Hint about .step file preparation

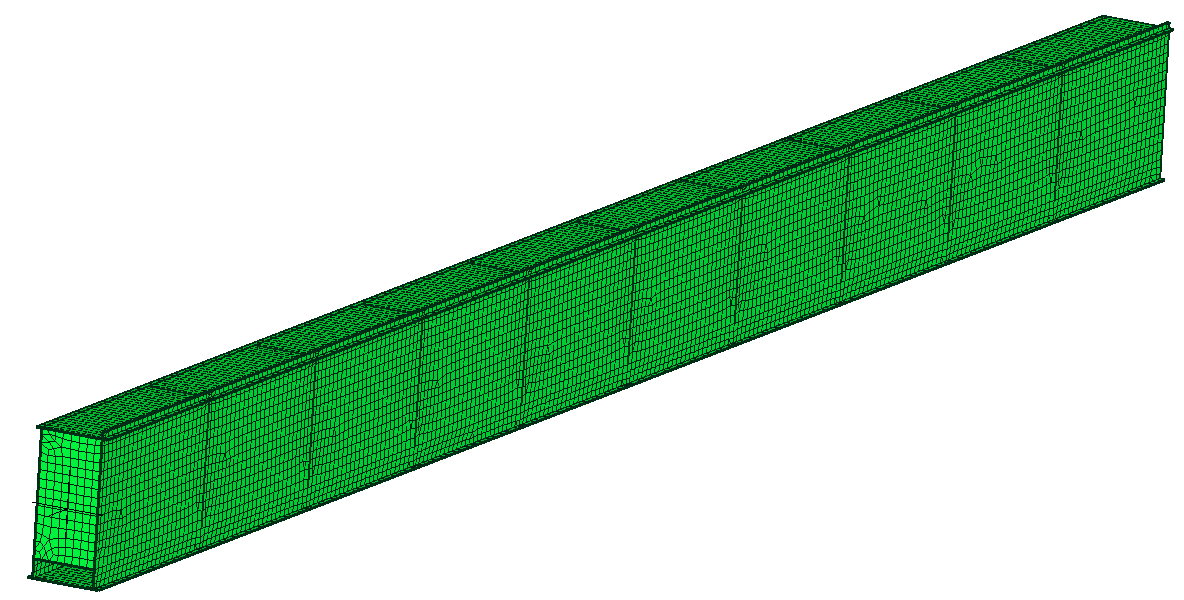

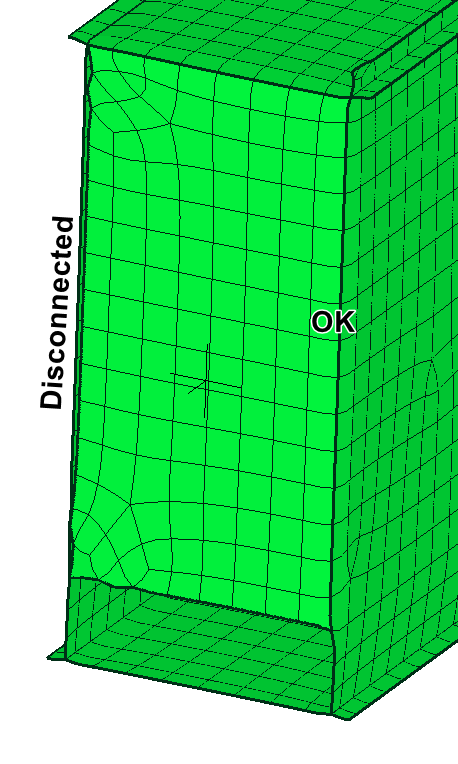

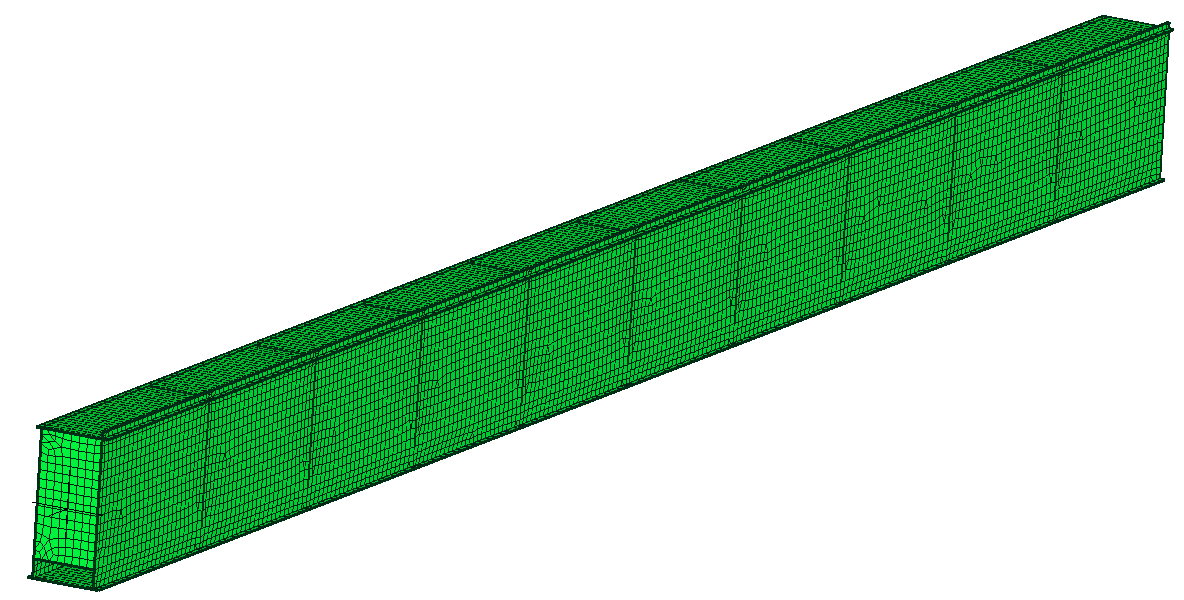

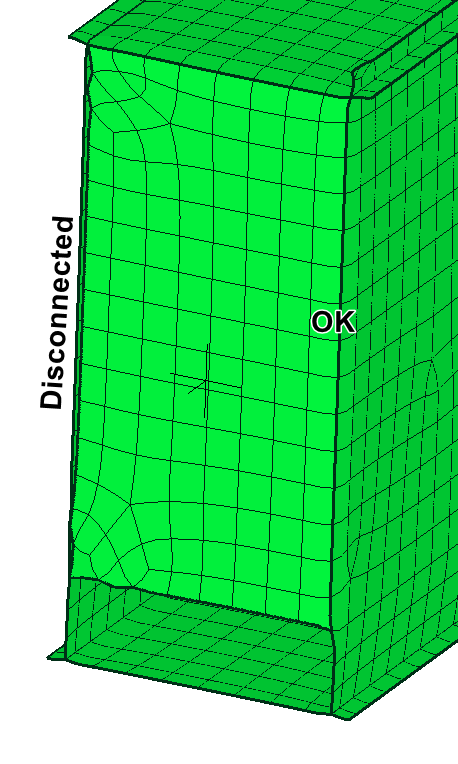

I often work with welded box section and so I prepared a CAD parametric model to build the complete girder (shell). The problem is that all the times I must import the step file into FeeCAD and apply fuse command because the diaphragms are always disconnected on one edge (see picture). All other surfaces (webs, flanges and rail) are meshed correctly

I use SW to build the CAD model

I use SW to build the CAD model

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Comments

I have made in the past some consultancy work on similar models and I remember that the CAD model were not perfect, lot of very small imperfections and I had to fight a lot to make it mashable with coincident nodes in Salome. Maybe you can just use "TIE" and don´t waste to much time looking for that imperfections.

Feel free to upload the models (native and step), maybe we could see if we found the gap.