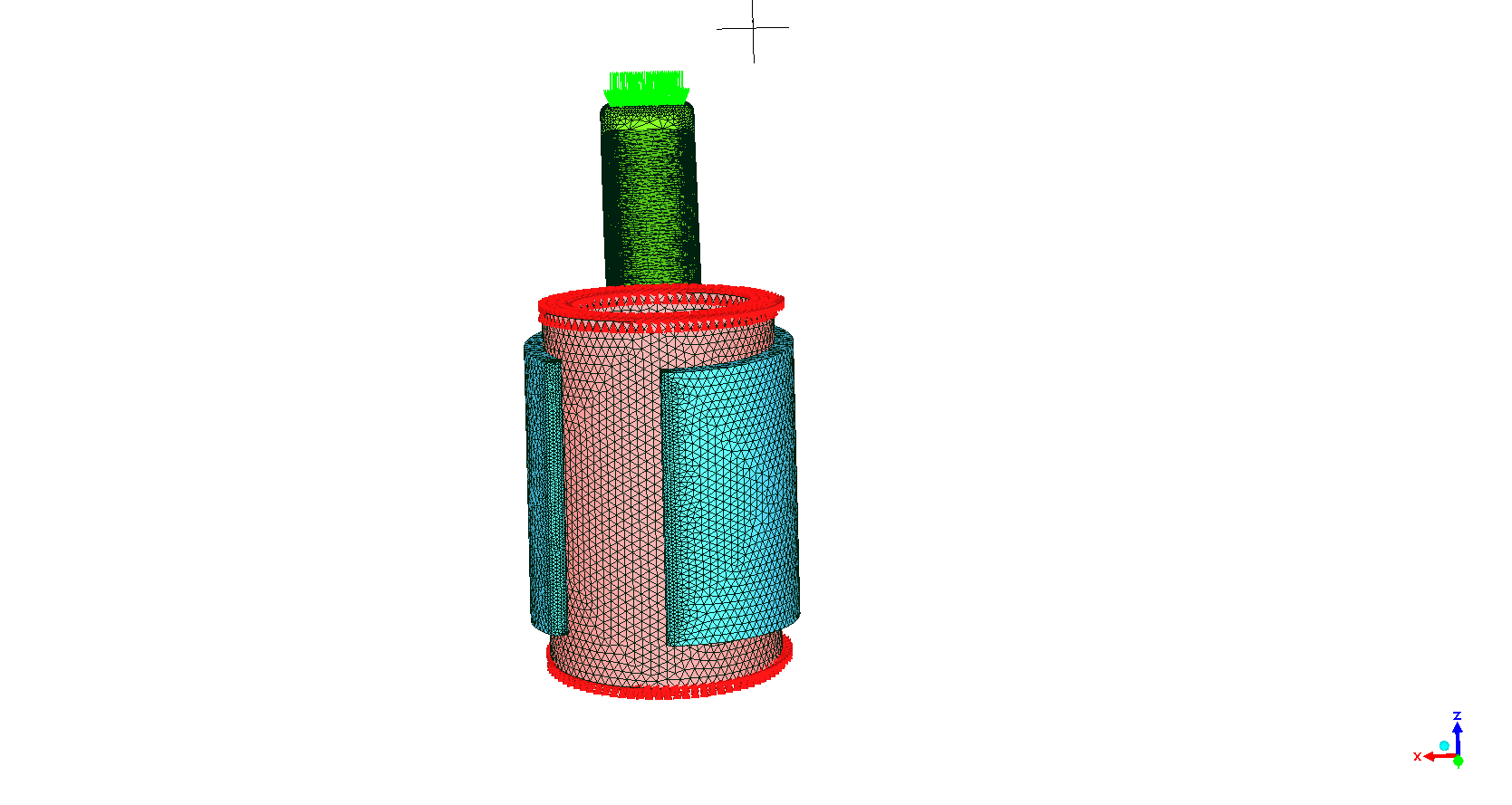

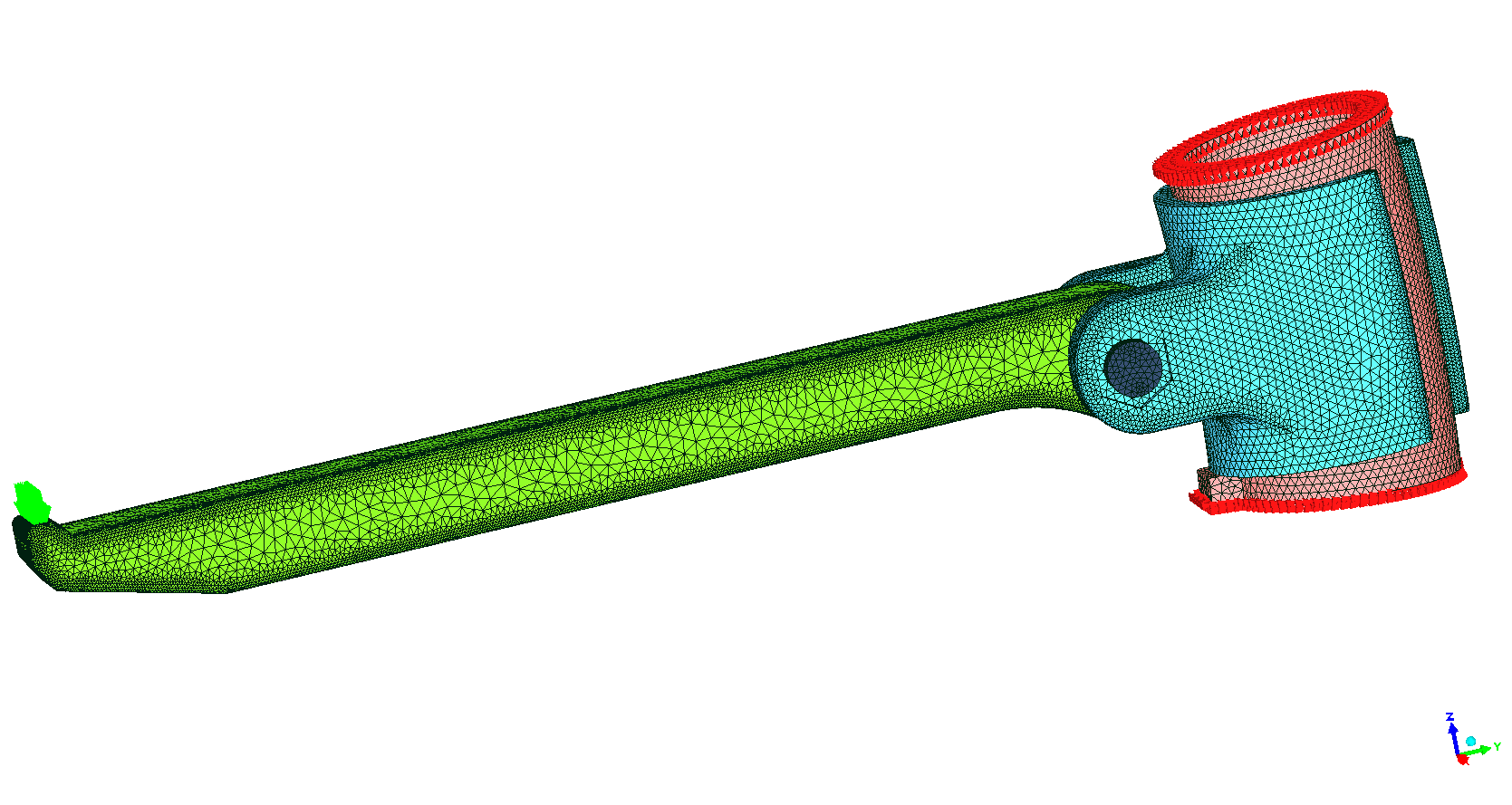

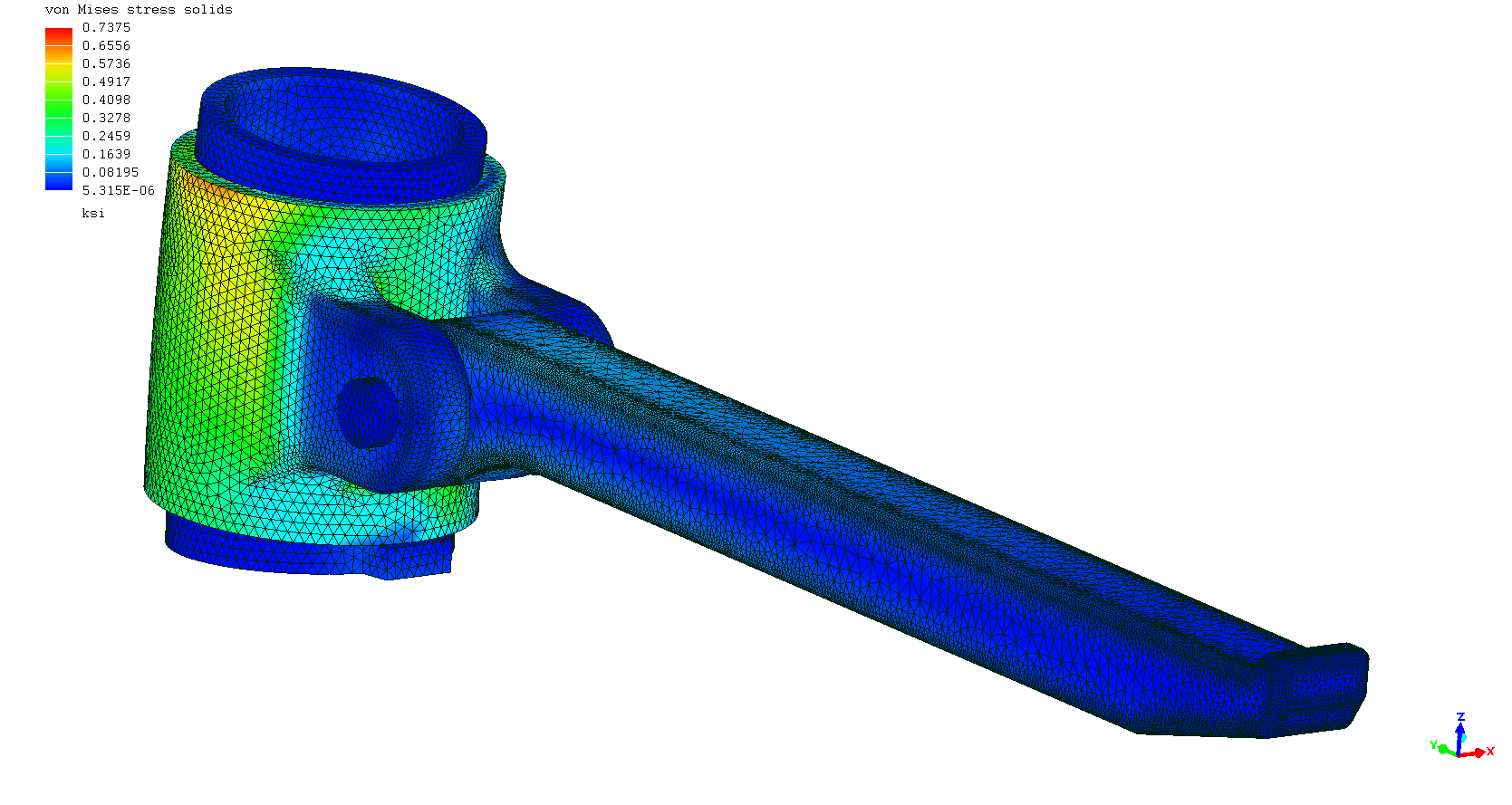

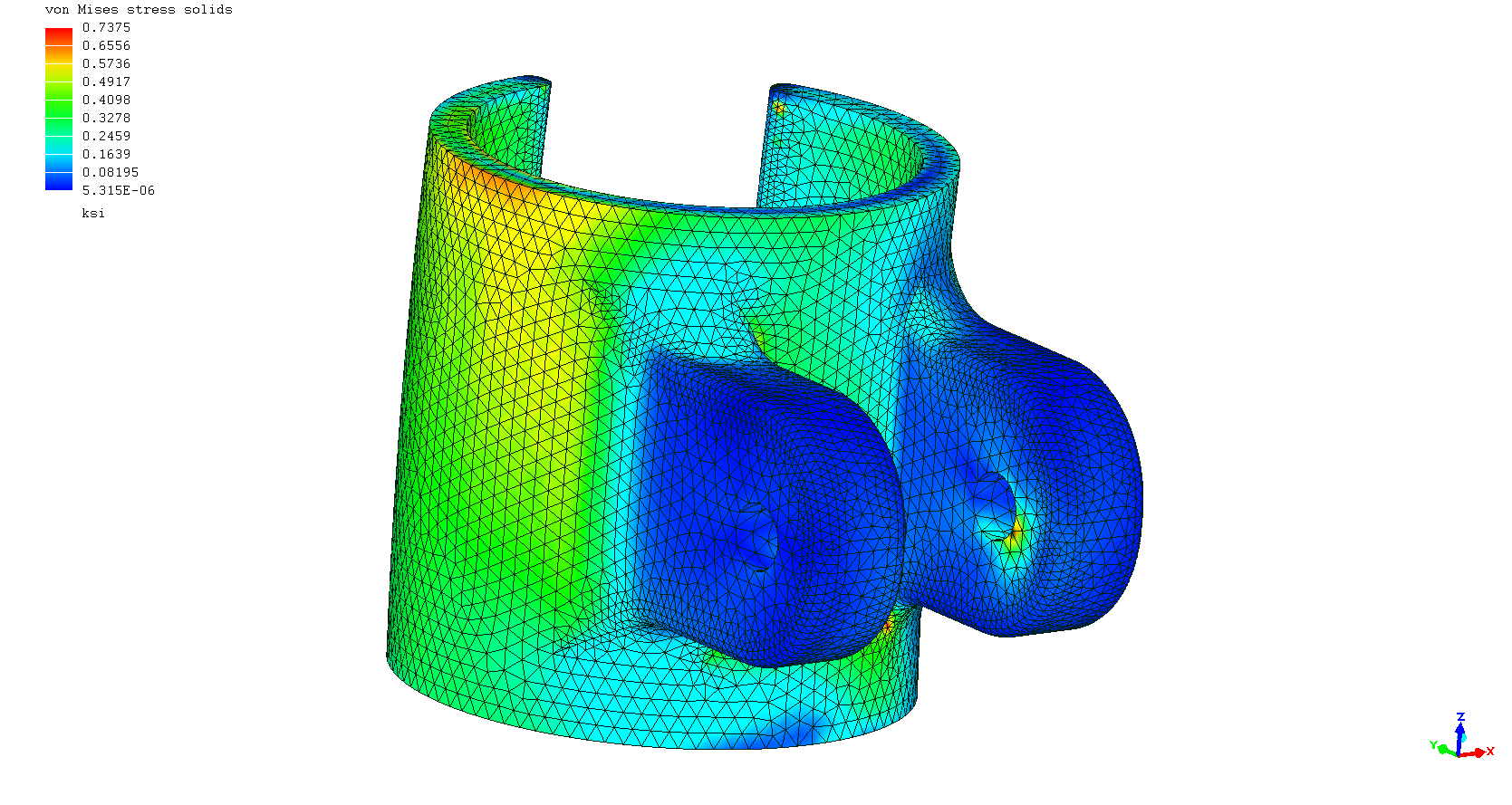

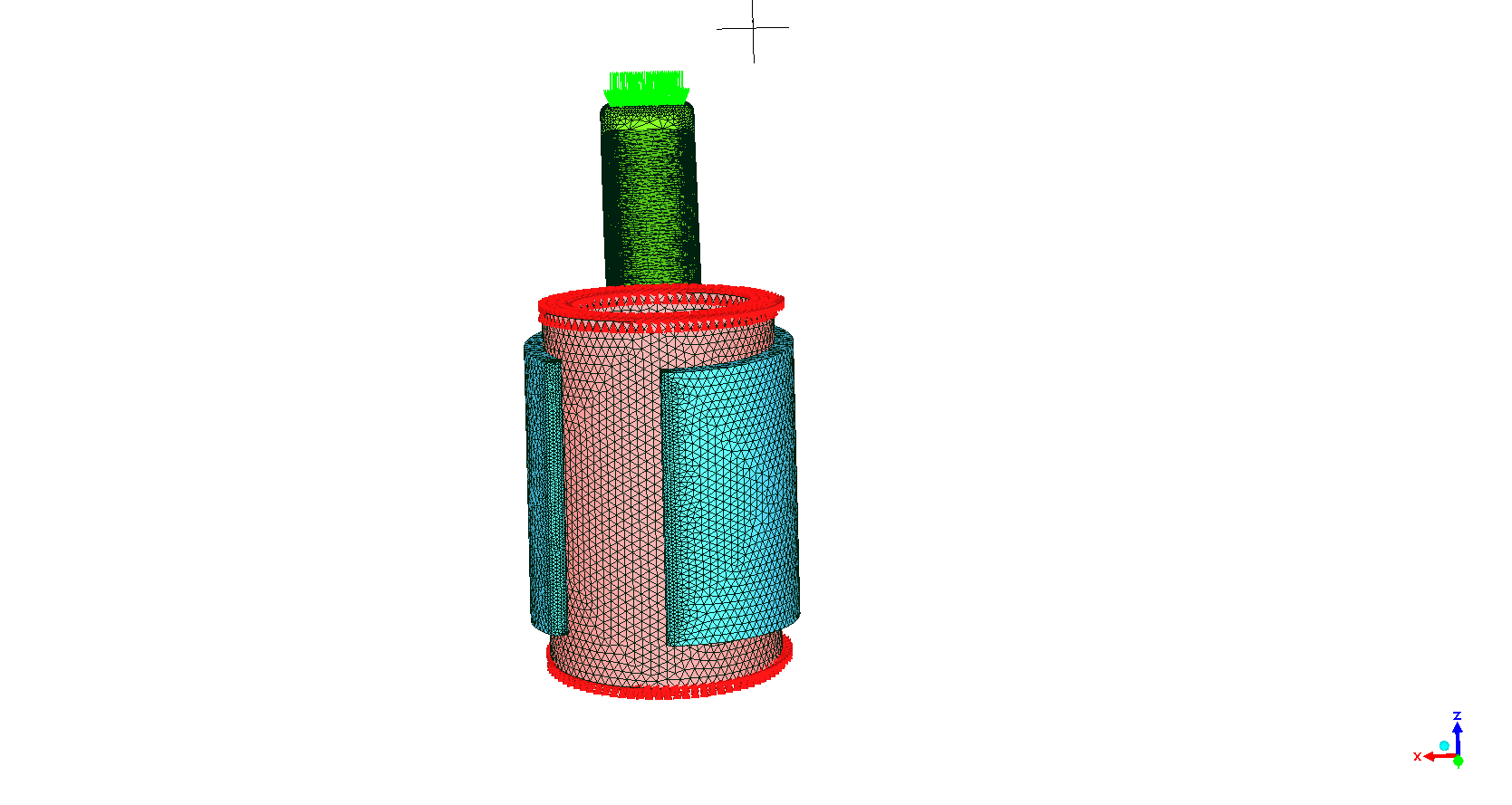

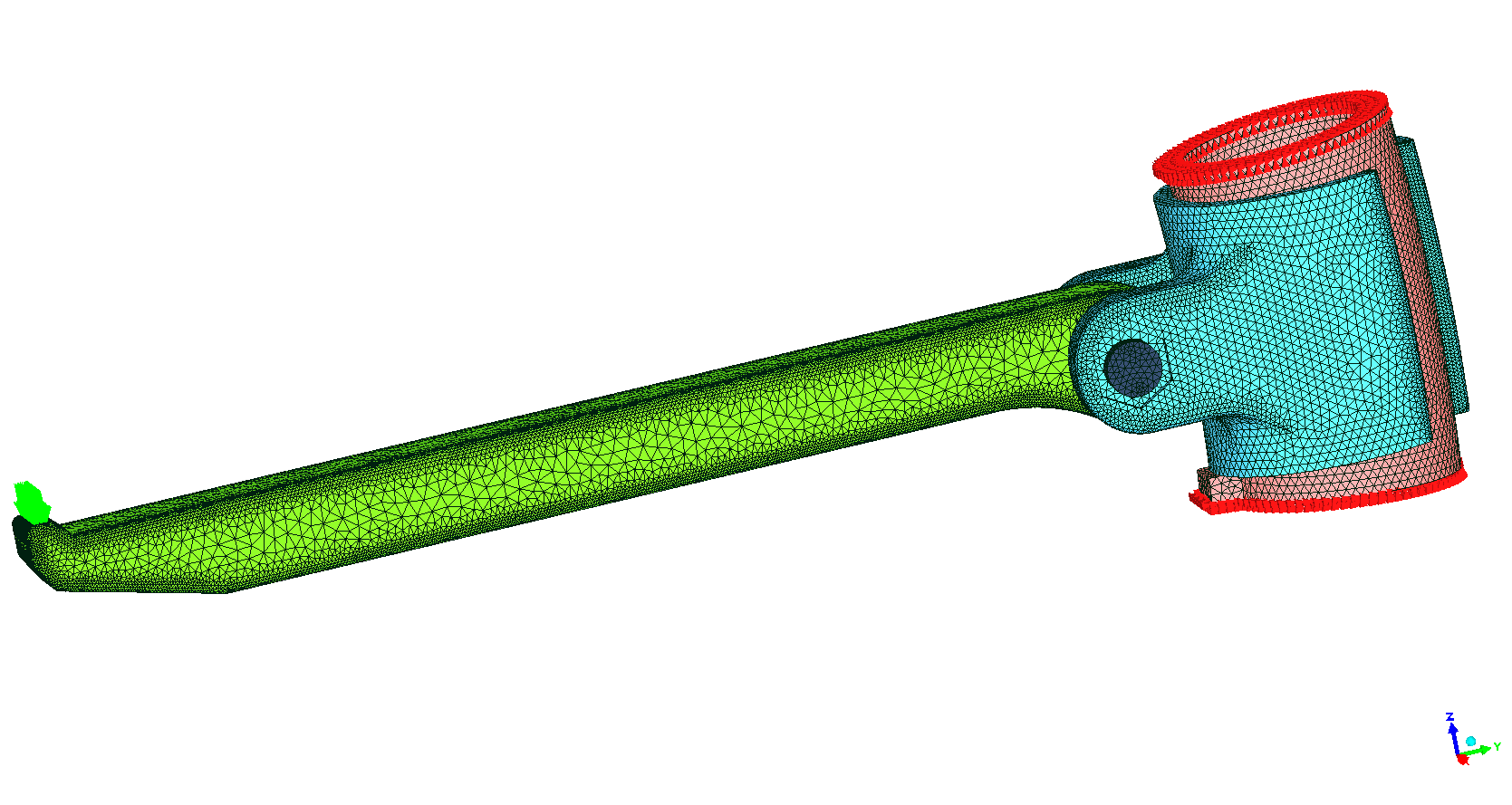

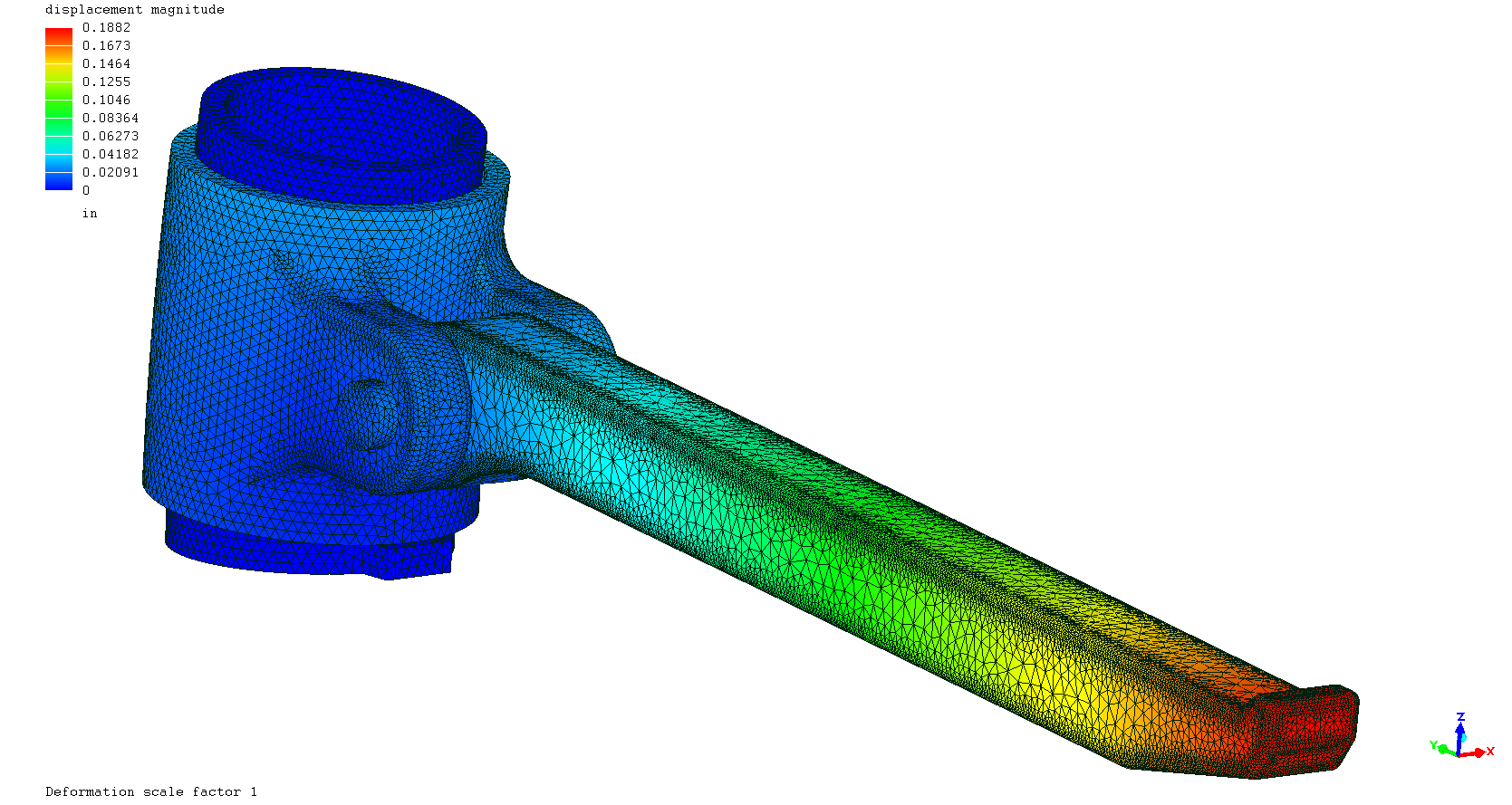

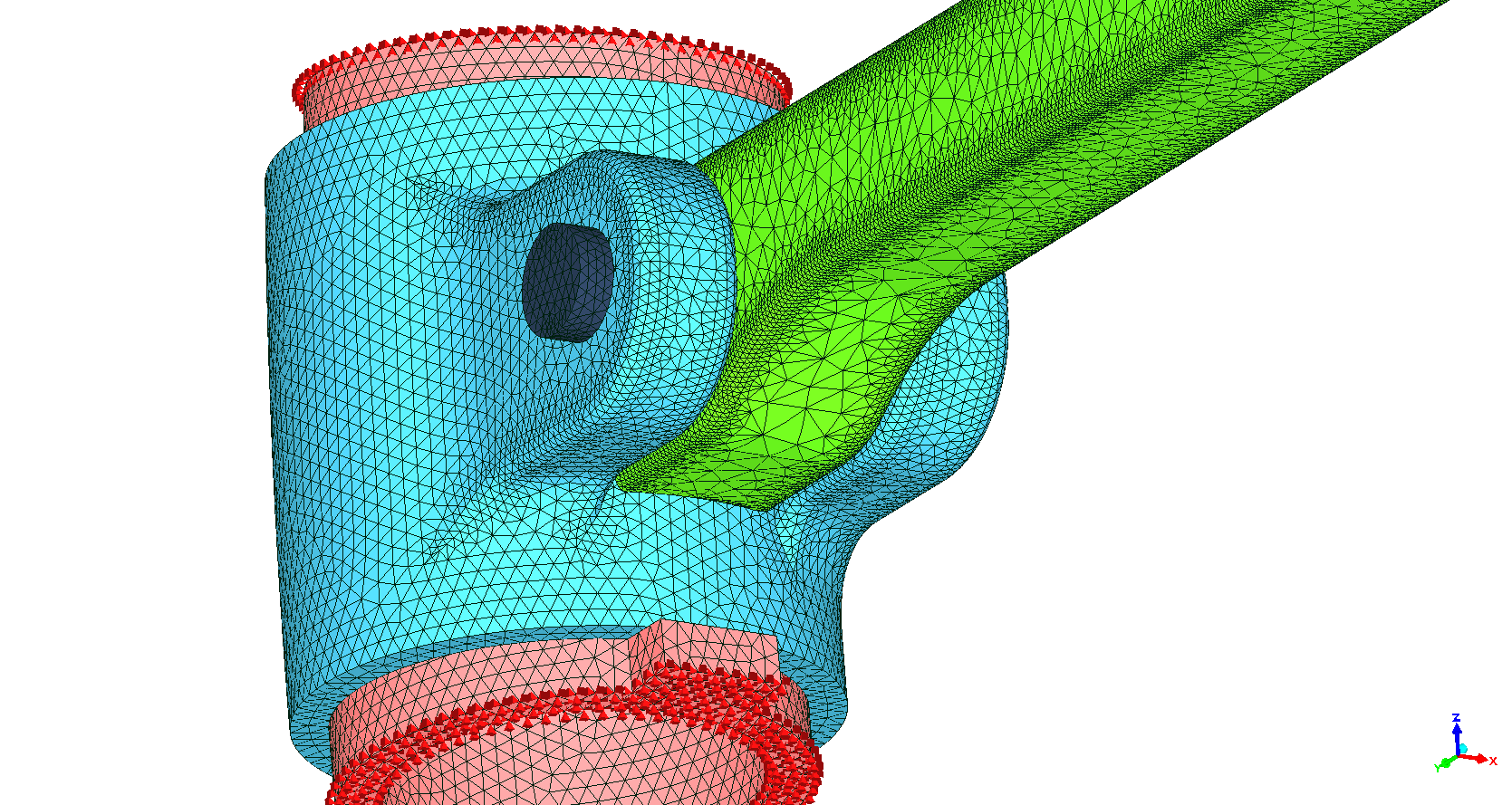

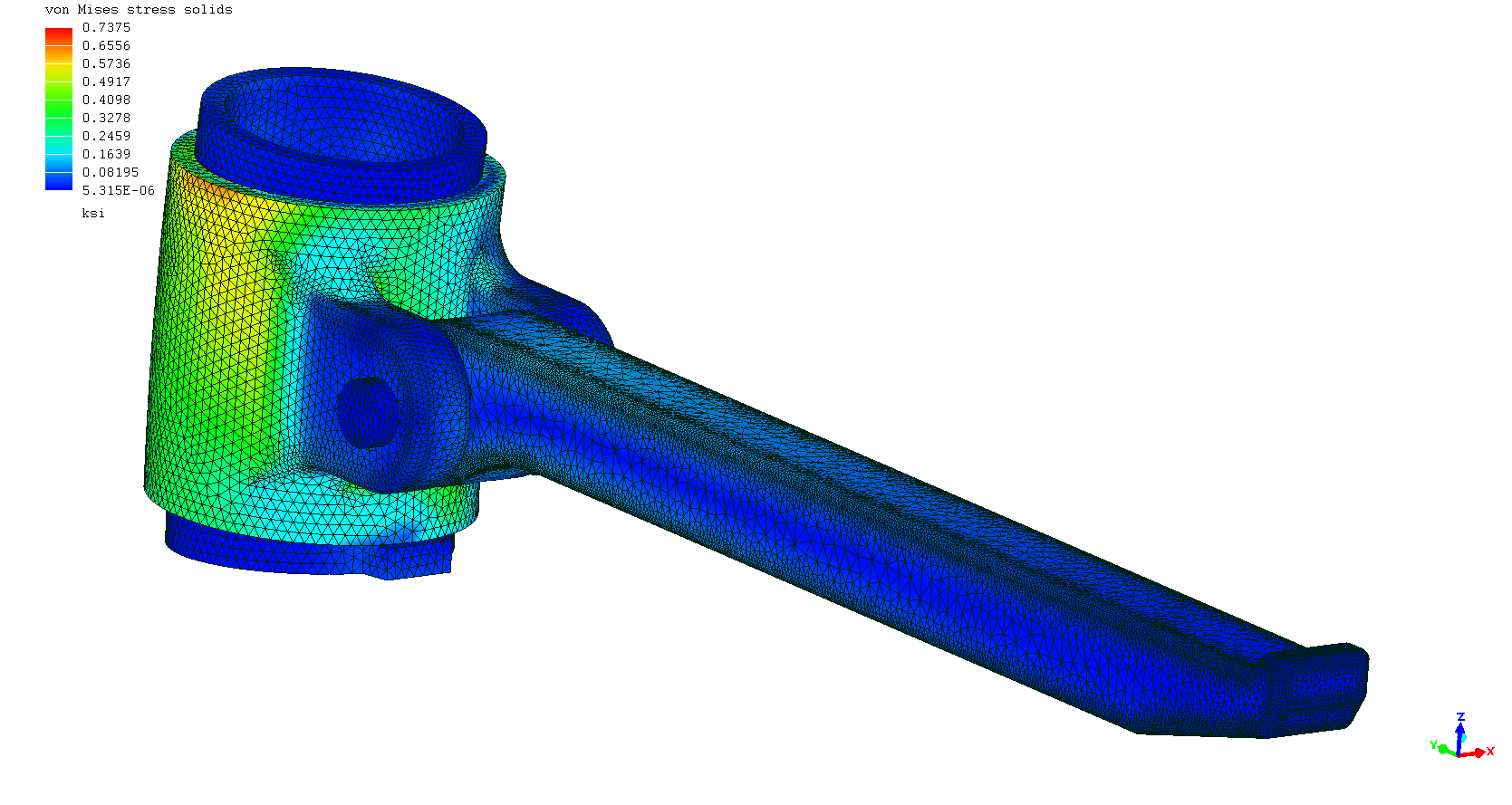

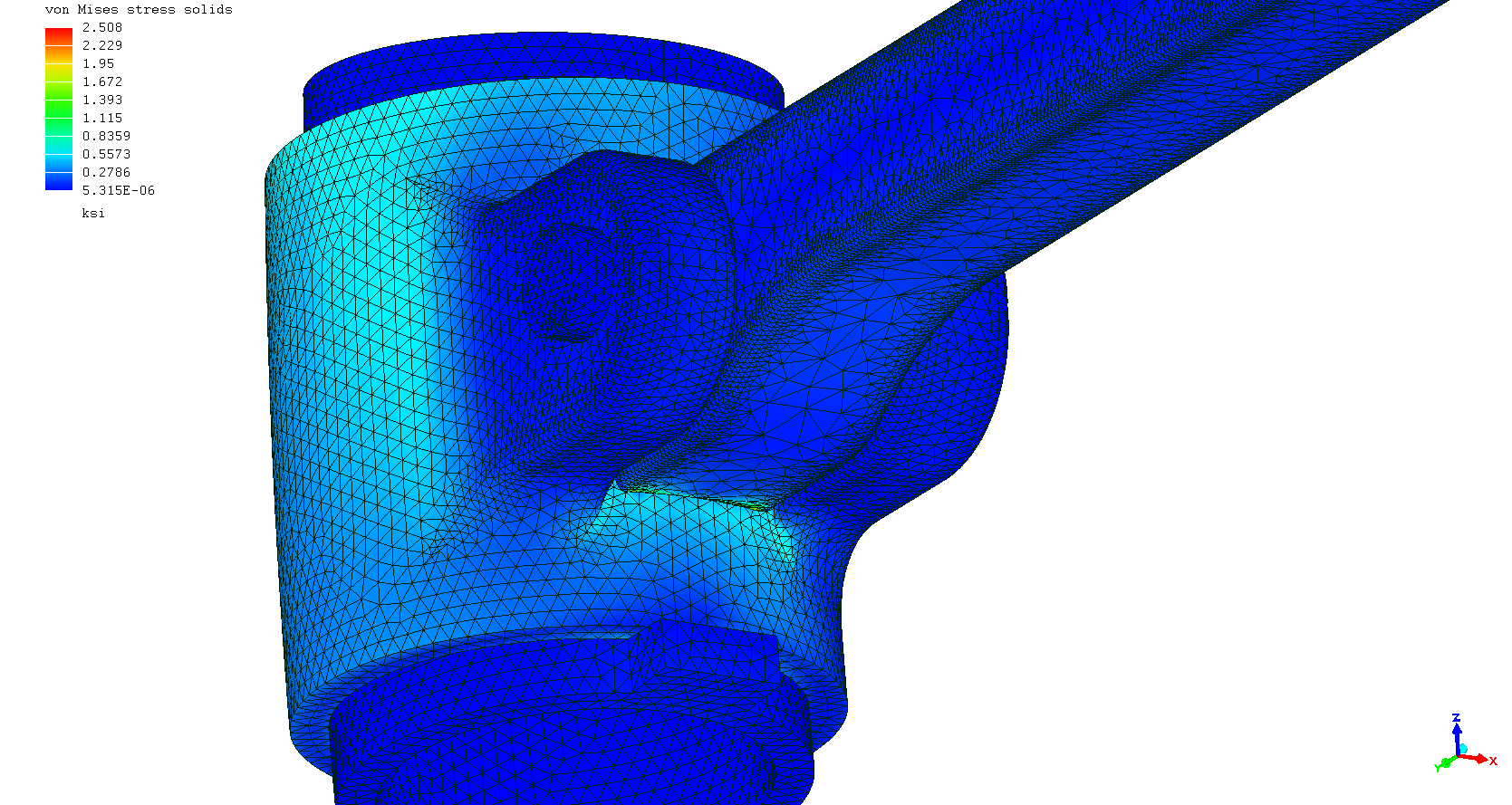

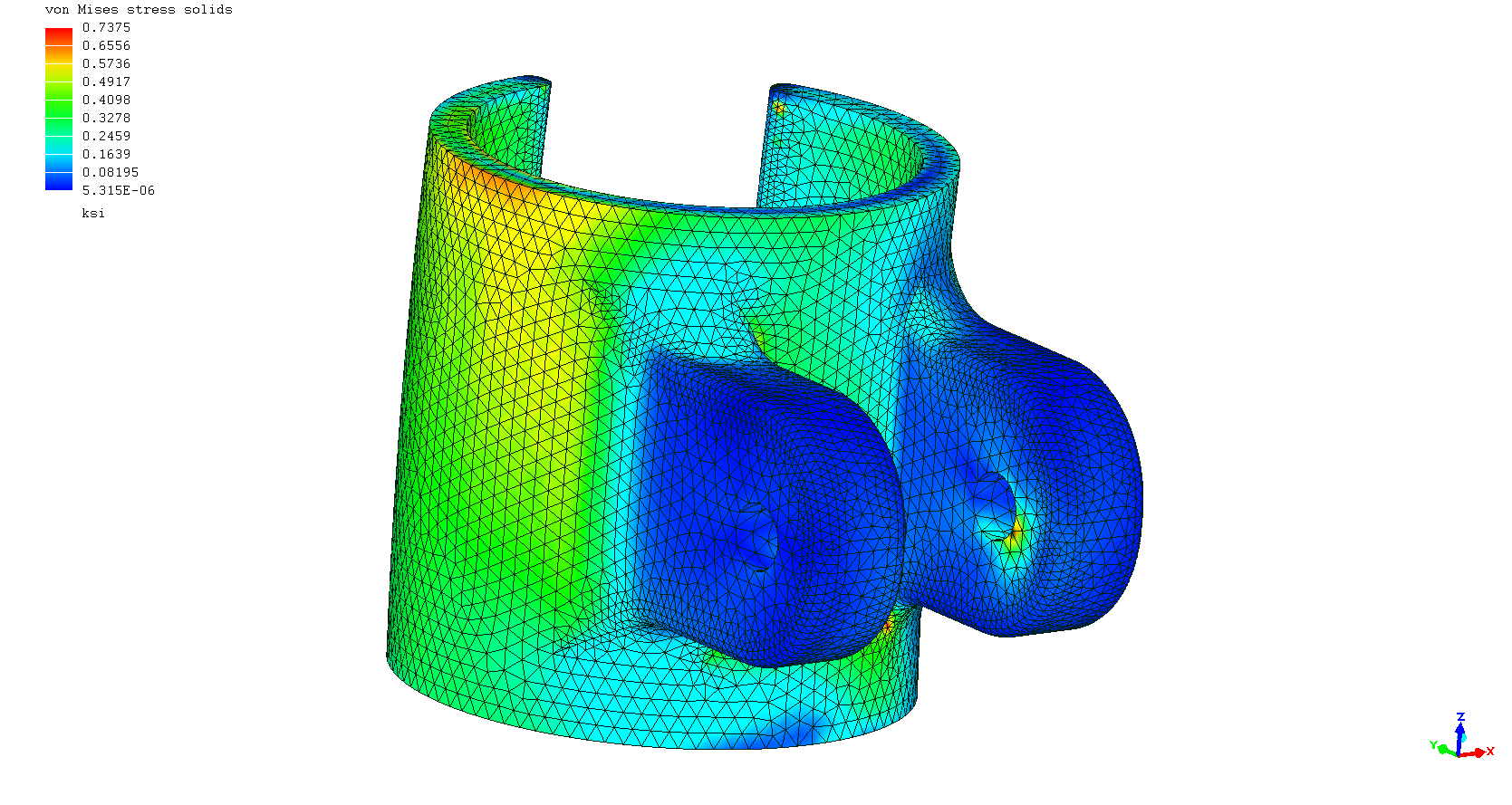

plastic clamp on curved metal bar

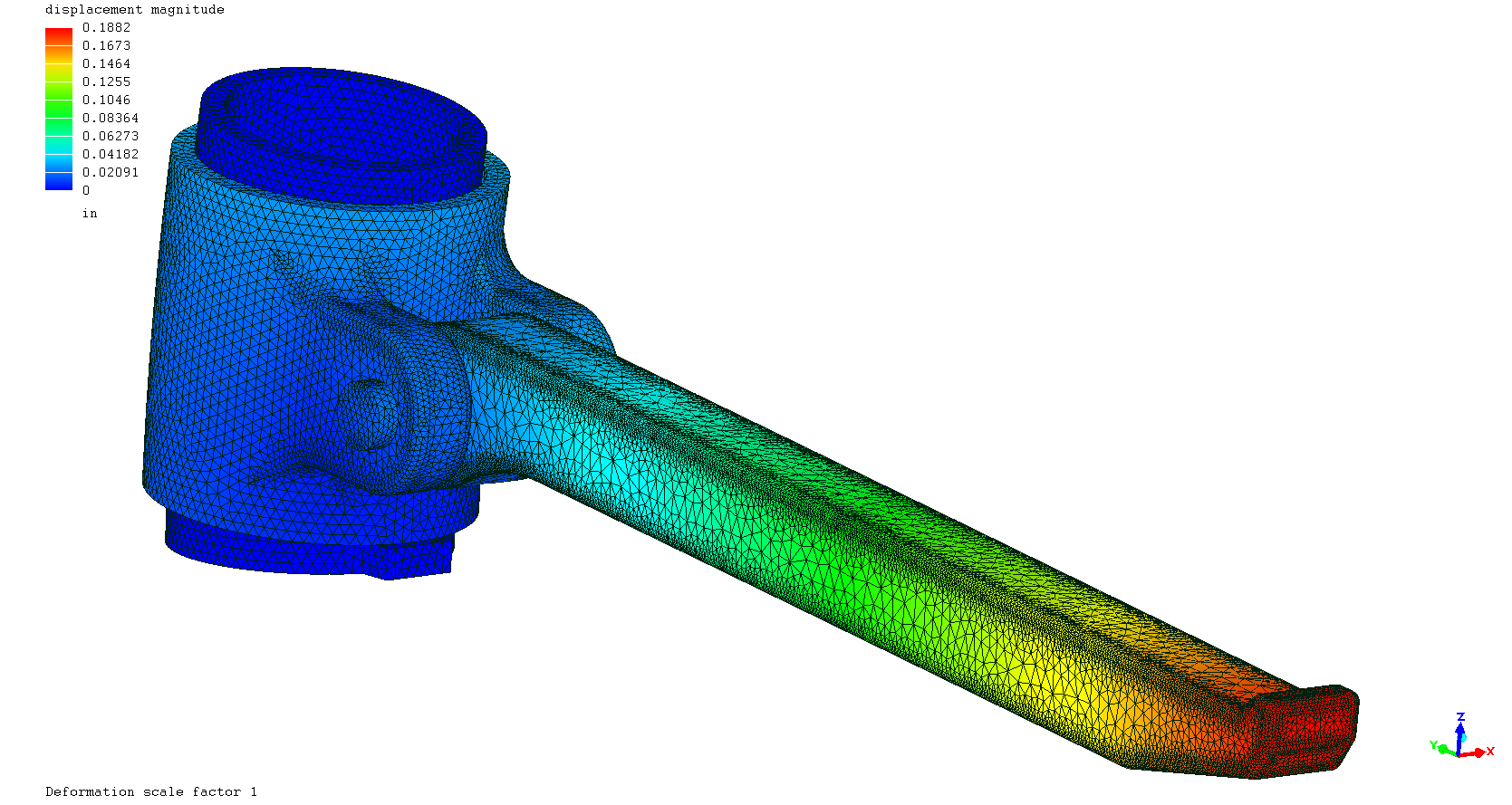

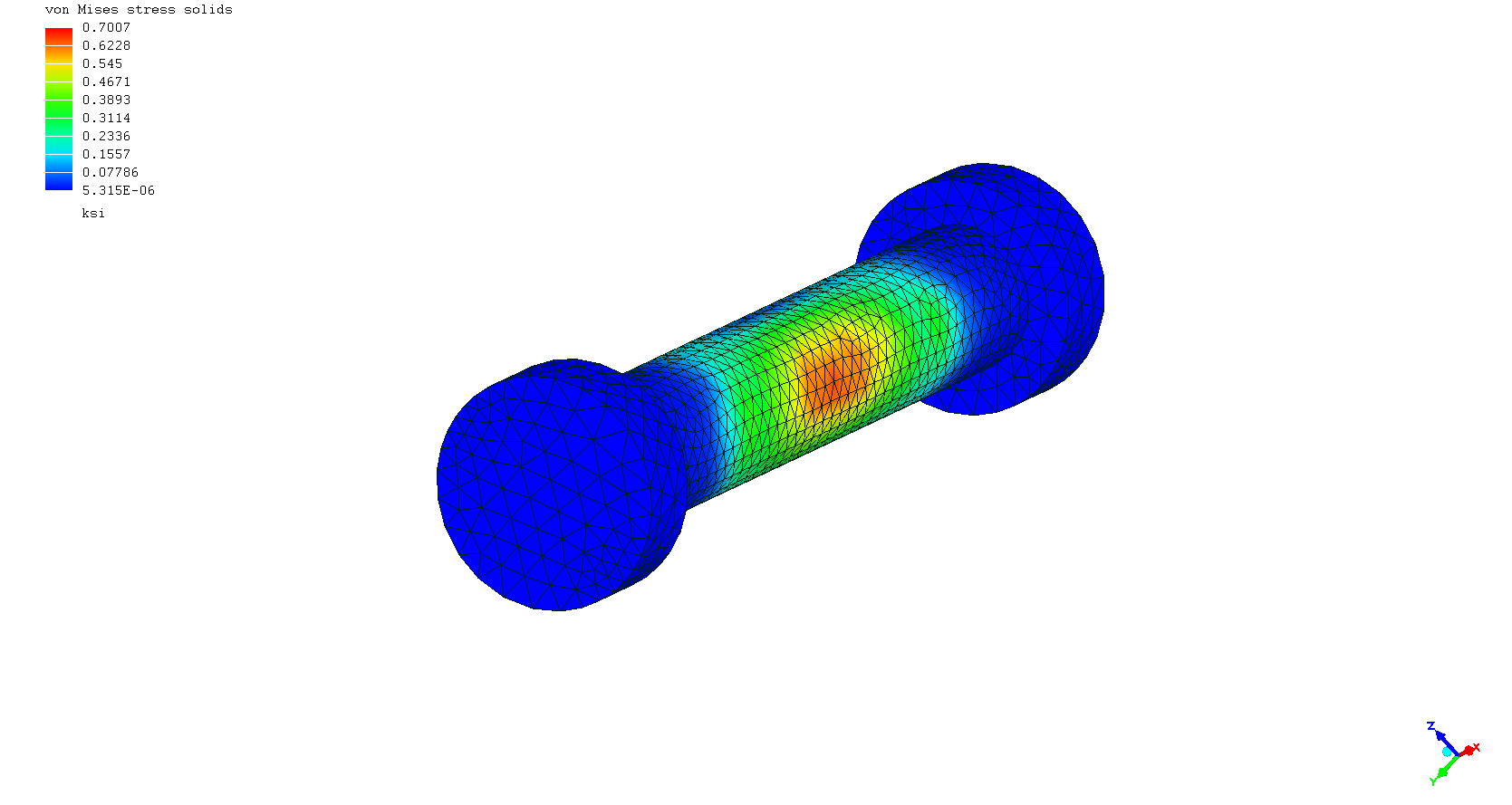

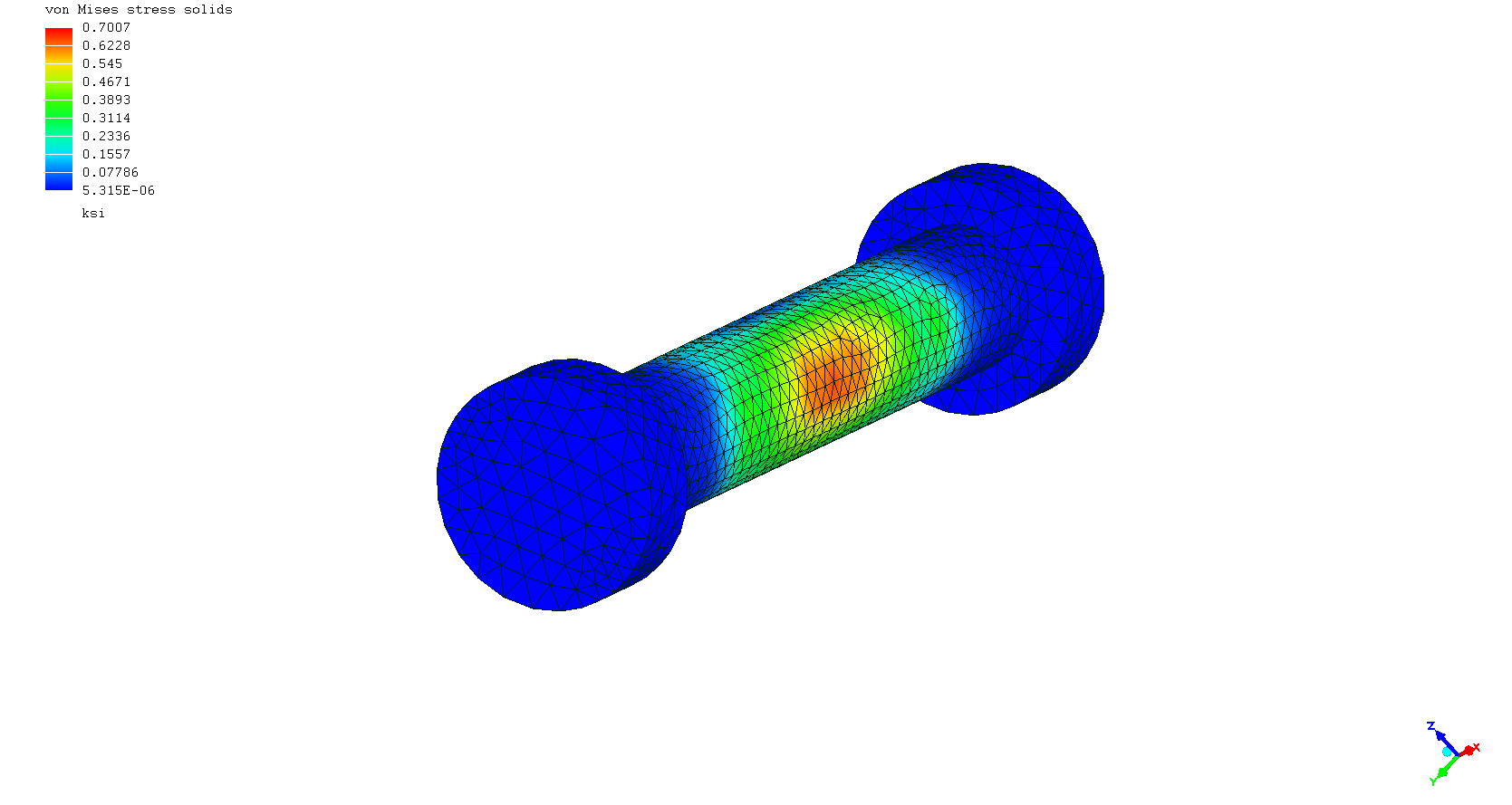

Contacts used a number of places. Installation is to snap clamp on to bar separately and then install the arm. Arm will support 0.5 lb at the tip with .2 in deflection.

Howdy, Stranger!

It looks like you're new here. If you want to get involved, click one of these buttons!

Comments

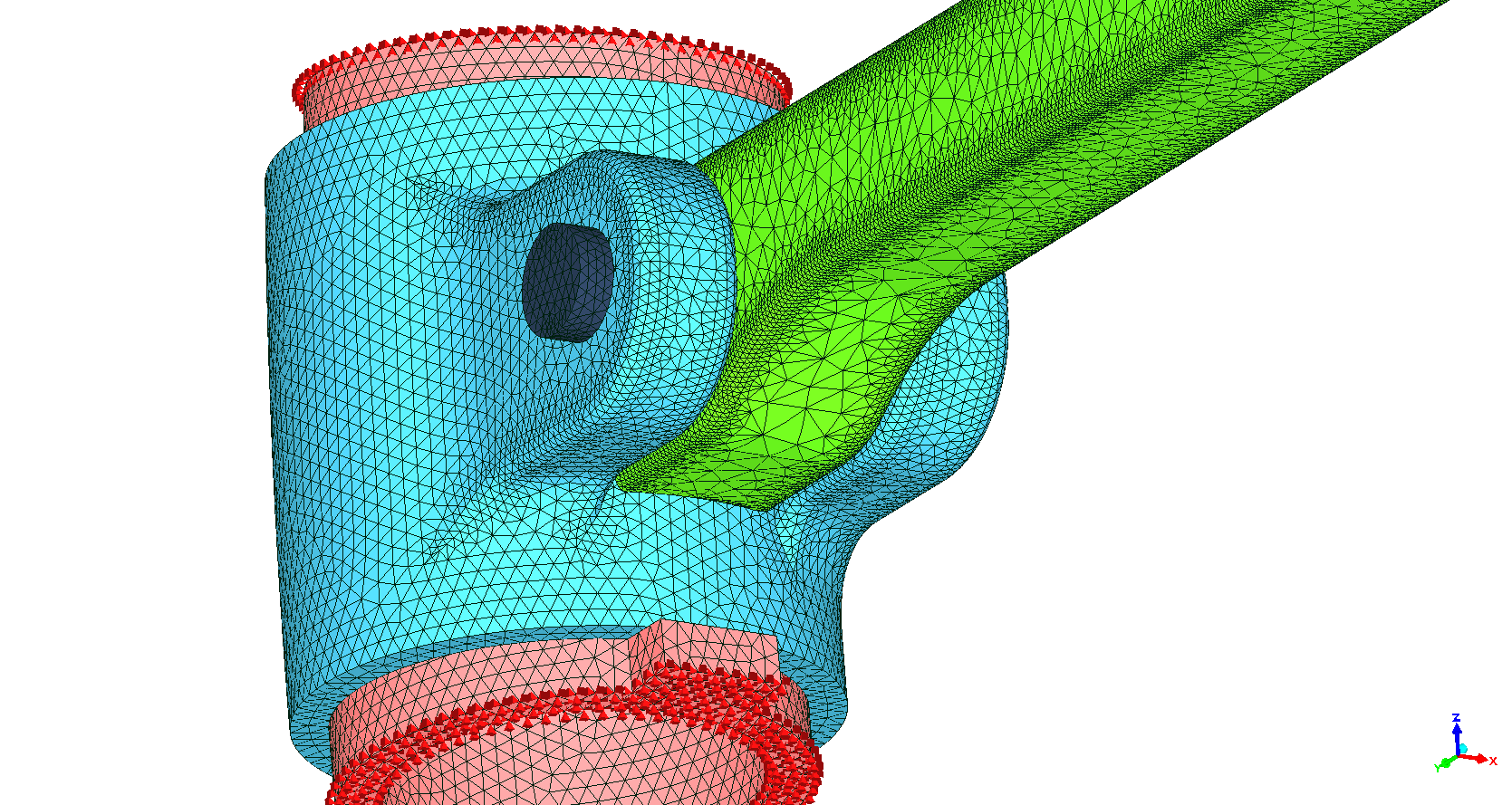

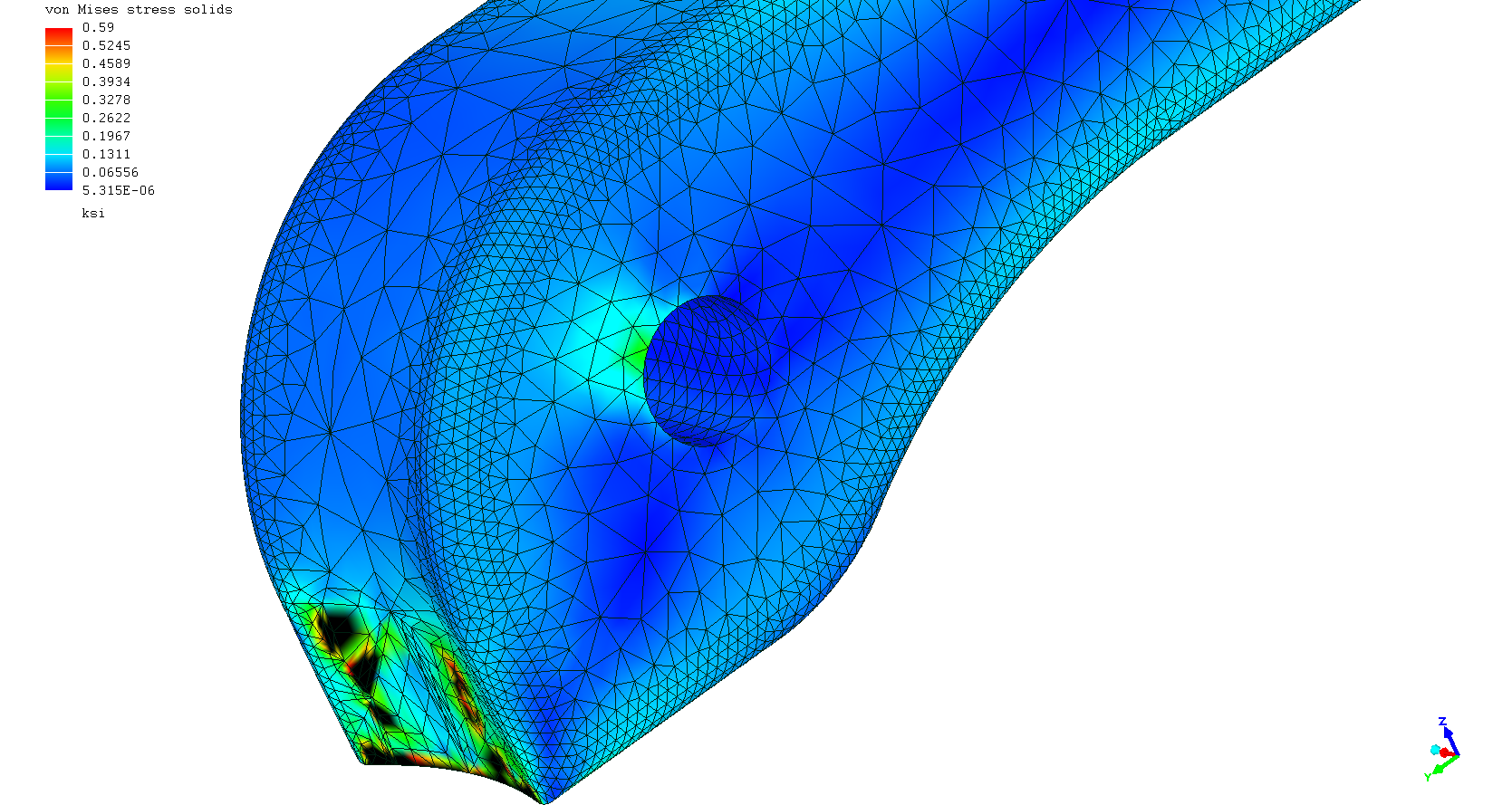

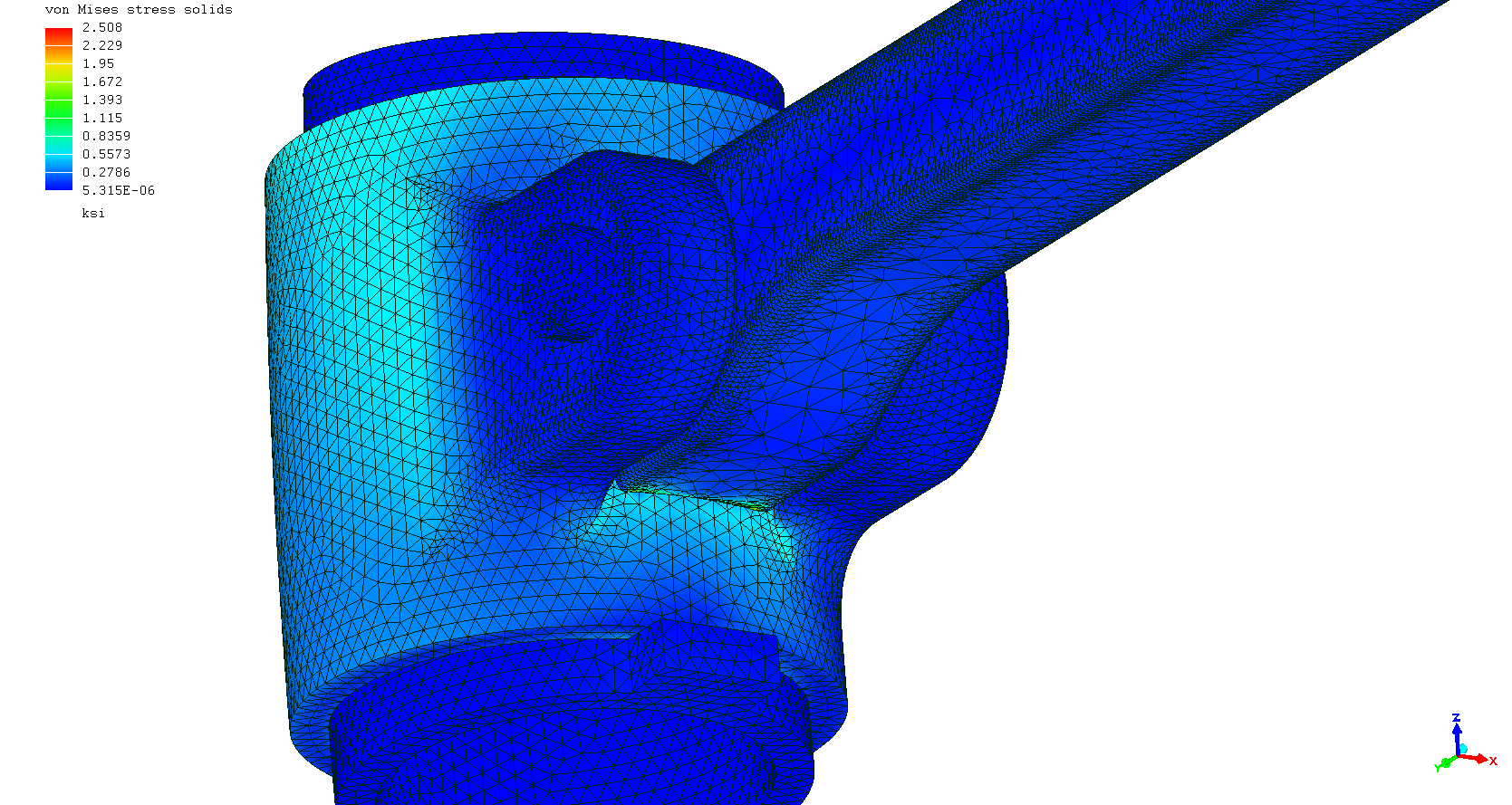

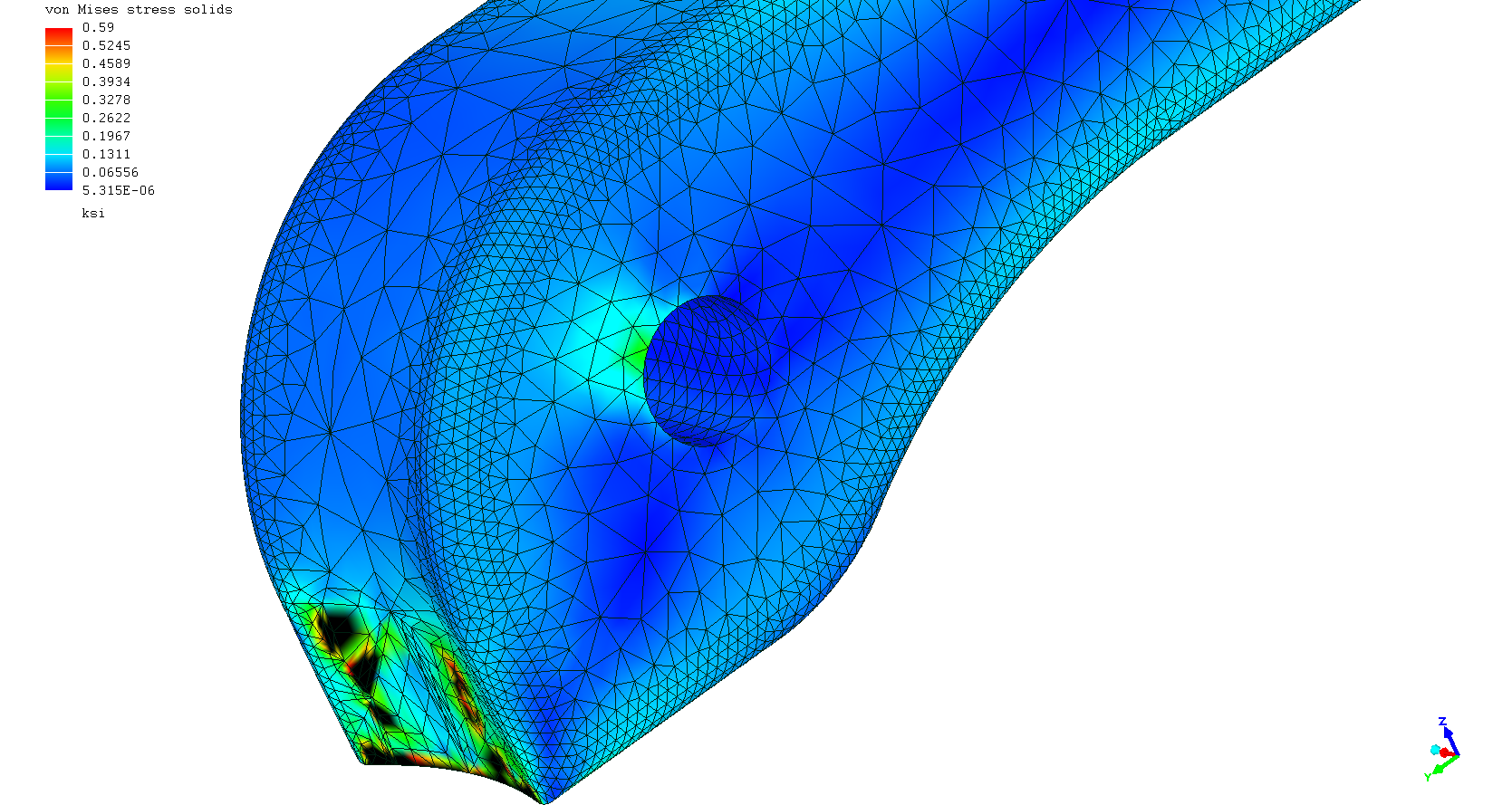

“a couple of things going on here, one, the arm to clamp interface”.

¿Which kind of contact are you considering.? I think you didn’t merge nodes as it looks like a free clamp that could open or slip but ;

¿Isn’t a phisical gap between the two components needed for convergence?.

¿How did you managed? ¿Only compression maybe?

Any information you could provide would be appreciated